Wire shelving systems from Closetmaid and Rubbermaid can provide a variety of options, but rooms vary in size, and the ventilated wire shelving comes in standard lengths. So, what’s the best way for cutting wire shelving to fit your dimensions?

Note: Elfa line of wire shelving isn’t designed to be cut by the consumer. An email response from an Elfa Room Coordinator states, “for our ventilated elfa shelving, we custom cut everything to fit your space”. The other option is using the pre-made lengths to fit the space best as possible.

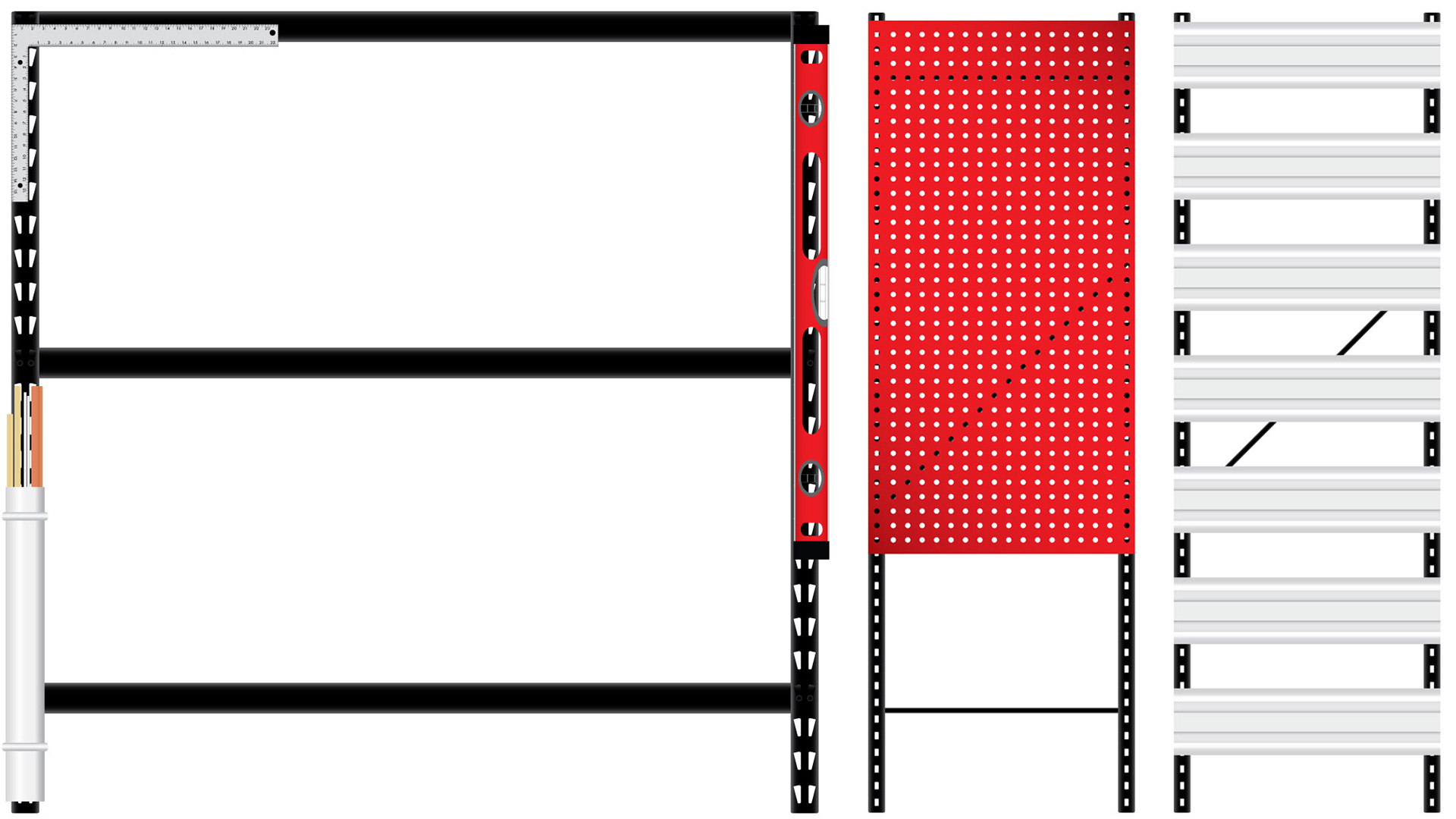

How to Measure: Read our How to Use & Read a Tape Measure – body measurement section for easily measuring inside corners and edges… from wall to wall. How much space you want to leave between the wall and shelf edge, depends on how much you want to maximize the storage space. A minimum of a 1/4″ will ensure enough space to install the shelving without hassle.

Home Improvement Store Cutting Services

- Positives – no cutting tools required.

- Negatives – (a) waiting to get the shelving cut. (b) spending extra time at the store, measuring and making sure the shelving was cut to the lengths requested. (c) making sure the employee makes clean and even cuts. (d) if there is a lot of shelving to be cut, you could have a time-consuming project at the store. (e) specialty cuts…like angles…may not be doable by the store. (f) unable to address any design and/or measuring changes without a trip back to the store.

Best DIY Cutting Option = Bolt Cutter

This is the same option a store will use to cut the shelving. Years ago there was a manual cutter by the shelving section to cut the shelving yourself. Nowadays the larger stores have an air operated cutter for employee use only.

- Positives – (a) clean and fast cuts. (b) no securing / clamping to workbench needed. (c) can cut both the large (main structure) and smaller (shelving section) diameter wires without the need for separate tools.

- Negatives –purchasing a tool that may not be used often, or ever again.

- Cutting information – A 12″ minimum bolt cutter will be needed to cut the larger diameter wires. The longer the cutter, the more leverage and ease of cutting. For our test we found a few cheap options available at any home improvement store.

Tip: Check your local home improvement store or other local tool rental stores for bolt cutter rental availability.

2nd Best DIY Cutting Option = Hand Hacksaw

- Positives – (a) purchasing and having a hacksaw can be useful for several other projects. (b) clean and fairly quick cuts can be made with the proper saw and blade (view article).

- Negatives – (a) much more time-consuming than a bolt cutter. (b) more prep work and possible modifications may be required.

- Cutting Information – Lay the wire shelving on a workbench; hanging the section to be cut off over the edge of the work surface.

Note: the use of a towel under the shelving can protect both the work surface and wire shelving. Hold the shelving firmly with one hand and cut with the other.

(i) clamping the wire shelving to the tabletop or workbench with tools like Irwin soft tip clamps can be very helpful to allow both hands on the hacksaw for faster and more controlled cutting.

(ii) shorter makeshift table can be made; then kneel on the shelf trying to hold it steady instead of clamping.

(iii) a tool like the Channel Lock Cutter, or similar, may be needed to cut one or more of the smaller diameter wires on the section not needed; allowing room for larger hacksaws to access the larger diameter wires to be cut.

This type of cutter is also a useful tool if having to make angle cuts. High tension saws will make the cutting process much quicker, and more precise than economical saws. Compact hand saws like this Milwaukee model are: more economical than larger saws, fit between the smaller diameter wires without modifications, easier to store, and possibly more useful for certain households.

Reminder: When possible leave roughly a 1/4″ at each end to fit an end cap to cover up the rough cut. The end can also be cut flush to the nearest wire edge, if that works out better for the space given.

Reciprocating Saw (sawzall)

- Positives – clean cuts if all the proper precautions are taken as listed below, and correct bi-metal blades are used.

- Negatives – (a) expensive. (b) wire shelving will have to be clamped tightly, to keep from vibrating, and this will require tools (clamps and a workbench of some kind). (i) when having to clamp the wire shelving, the surface can mar very easily on some brands. This can be prevented with the use of rags, towel, or soft tip clamps. (ii) a reciprocating saw is not a finesse tool, as it vibrates…and can jump around if not held steady. The shoe of the saw can also mar the shelf while cutting.

Jigsaw or Circular Saw

- Positives – clean cuts with the appropriate metal blade

- Negatives – (a) same as reciprocating saw. (b) you could spend as much on a metal cutting circular saw blade than what a cheap bolt cutter costs, and still have a more difficult job of creating a clean cut without the proper prep and measures.

Note: a saw with the plastic bottom plate adapter (to keep from marring the wire shelf when cutting) is useful.